The industrial field is facing an evolution, integrating new technologies and automation to better respond to changing demands. Switching and sensing technology are elemental in making these advancements possible.

Industries implement automation to increase productivity and reduce costs on human resources, their benefits, and other associated expenses, while increasing precision and flexibility.

With the arrival of automation, control loops were added to machine operation. These can be open control loops that allow for human input or closed loops which are fully automated. Industrial control systems (ICS) allow for monitoring and control locally and remotely. With these increasingly advanced control mechanisms, industries can operate 24 hours a day. Productivity has increased, errors are reduced and quality is improved.

Recent advancements in automation in industrial production are focused on flexibility and quality. Manufacturing flexibility not only allows for more product types but also lets consumers order customized products that are automatically produced.

Unionwell micro switches G9/G5/G6/G5W11/G11 Series are widely applied to industrial automation--automatic production lines, machine tool control, automatic lubrication system, etc.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  tiếng việt

tiếng việt  Türkçe

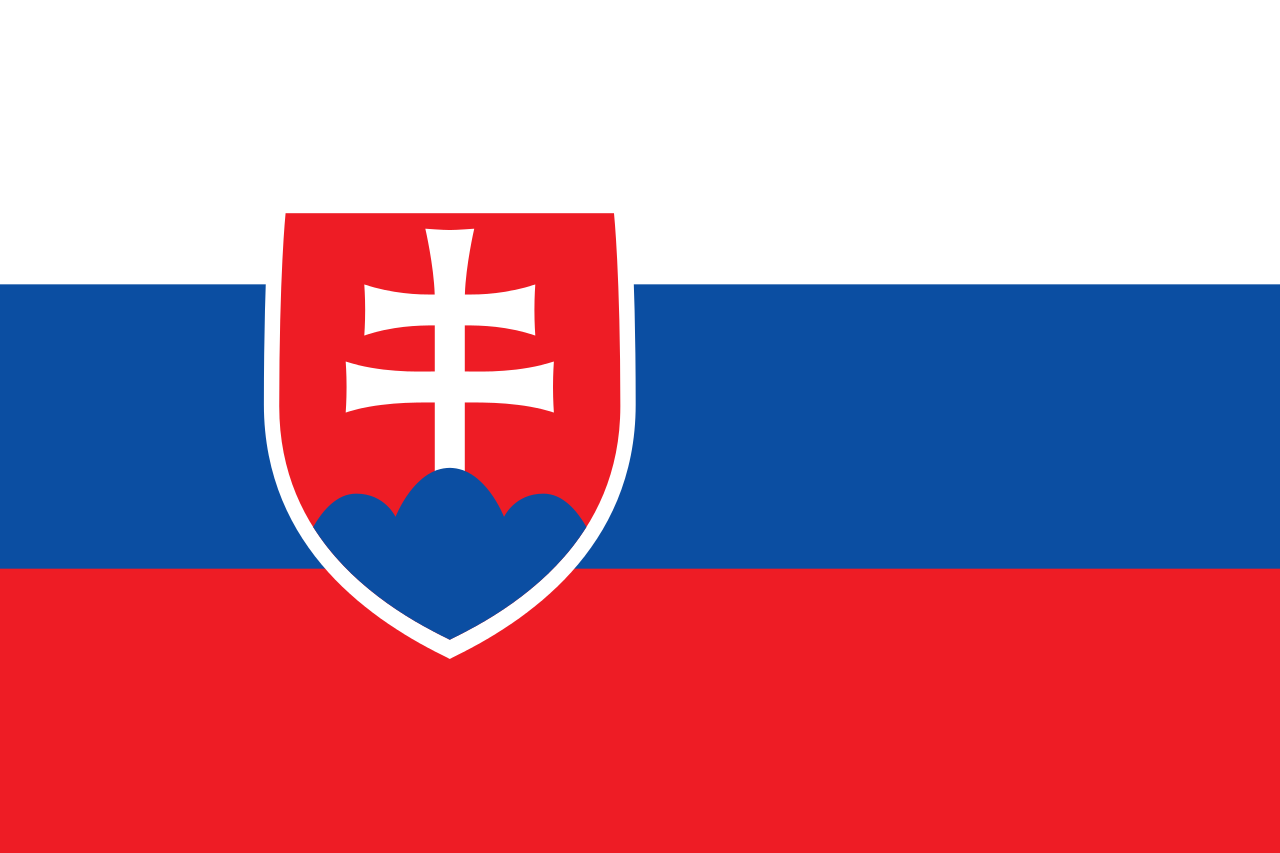

Türkçe  slovenský

slovenský  slovenčina

slovenčina  беларускі

беларускі

_20250411104120.webp)